We’re concentrating on Christmas calm this year, rather than furor. One thing in particular has helped: We started gift-gathering in mid-March. We concede we’re late in helping you, given that only 23 days remain until the squealing—in delight or dismay—starts, but maybe these shortcuts will help all the same. It’s research, not acquisition, that generally gets the teeth grinding. Here we go.

Hornady Lock-N-Load Progressive Reloading Press

We concede right out of the chute that we won’t do the Lock-N-Load justice—we’re not even sure that’s doable in a couple thousand words, to say nothing of what’s helpful in the “get it for (or as) a gift,” and “get it right now!” context.

That doesn’t change the reloading equation one bit at the highest level: Used as intended, modern gear will give you superb quality and reliability at still substantial savings. Better still, it will give you precise control over the ammunition you use in your individual firearms. This is the real reason to get started.

A Hornady Lock-N-Load will do all these things, and add impressive speed to your ammunition building as well. In manual-only mode—meaning ready brass and loaded primer feed tubes, but no bullet or case feeder—a relaxing pace will easily crest 300 rounds/hour.

Think about that: Between $60 and $150 worth of cartridges (depending on caliber) per hour that aren’t one-size-fits-all, or only run your gun 95 percent of the time, or only deliver ho-hum accuracy. Huge ranges of bullet and powder choices are open to you instead, and with potentially match-grade results. (Our own March 2017 transit of USPSA Optics Nationals is a case in point. We used a comparatively strange combination—including a smooth-feeding but atypical Hornady bullet for 9 mm—yet the formula delivered “A” hits in the 98th percentile across all shooters (331) and divisions, and zero malfunctions over 20 stages and 481 rounds).

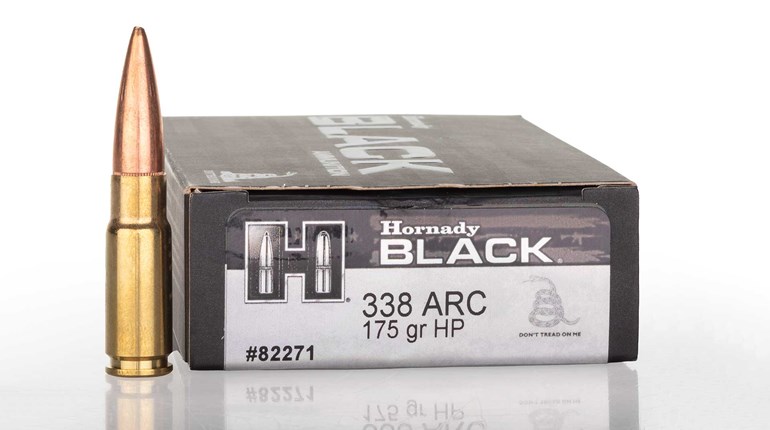

This is no diatribe against factory ammo, mind you: It’s great stuff in many circumstances, and we—oh darn!—have to shoot quite a bit of it. Hornady turns out some of the very best, in fact, but even they recognize there's no hope of optimizing for every gun, shooter and situation. You and your firearm(s) are a unique dynamic and ergonomic system, meaning the results will sometimes be splendid, and other times, well, not so much.

In the end, this may be why the Lock-N-Load is so good—as ammunition manufacturers, Hornady designers and engineers really know what reloaders need in a reloading press.

An exceptionally “open” plan—thanks to a large shellplate—is where it all starts. In conjunction with exceptionally smooth progression of cases through the tool positions with every pull of the lever, nearly 25 percent more room to work means the “oh s%@t” turmoil of tighter set-ups can simply be prevented.

More cleverness heads off the common newbie hazard of crushing a primer and lighting off an entire feed tube. Doing so is possible in virtually any progressive press, by the way, but a steel sleeve vents this mischance straight up and out of harm’s way in the Lock-N-Load. (This will rightly alarm you if it ever happens—remember, never force anything while reloading—but we also think it’s very unlikely in the Hornady system. All the same, safety glasses are a must.)

Case sensing at the charging position is another major plus for reloaders of all skill levels: Nothing kills an assembly run like powder dumped in the guts of your press. You have to try to do this on a Lock-N-Load. A sort of flip side here is that it’s also really hard to build a squib. These powderless cartridges are multi-faceted hazards, but we know of no press that affords such an easy look down into the case to verify charging. If you run a powderless case to the bullet seating position, you’ll have no good excuse.

As we noted, it’d be easy to go on and on. The speedy, bushing-based die swapping system handles multiple calibers—including rifle up to .45-70—and the ability to expand the system to much higher throughput (600-plus rounds per hour in our tests; case feeder here, and bullet feeders here and here) are just two examples of why we’re calling an arbitrary halt.

It sets up perhaps the best intelligence of all, however, useful for either gift-giver or gift-specifier. Take a look around, and you’ll routinely find the Hornady for around $400 (our friends at Midway, for instance). If you’re starting with nothing else, you’ll need a powder measure, dies and some components, too.

But any way you slice it, for about $600 you can have cartridges of your own making by New Year’s Day, and for many years to come. While Hornady’s Lock-N-Load is way too substantial to be a safe stocking-stuffer—you’d need one heck of a mantle—we doubt there’s a non-reloading shooter who wouldn’t be delighted by one under the tree.

Visit Hornady here.

EGW Undersize and Lee Factory Crimp Dies

OK, we kinda set you up with that stocking stuffer quip, because we do, in fact, have a couple of great ones. Better still, both stick with our reloading theme. Best of all, we’ve used these ourselves with excellent results for years: If there’s a consequential problem, it has escaped us altogether.

When it comes to the EGW Undersize sizing dies, we have a confession. We actually keep new ones around to pass on to puppy-eyed friends who “see the light” after we demo them. The short version is correspondingly simple: As a replacement for standard-dimension sizers, these go into your assembly line in the same location. Their carbide sizing insert, however, is .001” smaller than spec, and this lets them attack, so to speak, a host of problems that can otherwise plague the volume reloader. If nothing else, they cut way down on pre-loading inspection time.

Mostly, their benefit is in restoring over-expanded cases with a tighter diameter (the mostly out of date but so-called “Glock bulge”), and by sizing farther down the case. If you’ve got the rest of your reloading gear running properly, you’re likely still encountering 2 to 4 percent of finished cartridges that don’t really run as you’d hope, but this gets cut by two-thirds with a EGW in the appropriate caliber.

That last percent or so can be captured by our Lee Precision recommendation. By name, it’s their Factory Crimp Die. This clever marvel essentially does a post-assembly resize to your entire cartridge as it closes the case-mouth flare. This assumes you’re seating and crimping in separate steps, of course, which we always recommend.

We know these are derided in some circles as capable of over-crimping (which harms accuracy by damaging the bullet), but we don’t have and haven’t had these problems. If you do, we bet you’re using lead projectiles, and there’s a simple fix. Remove the top plug, and clean it. Lead bullet lube gets scraped up here a little bit at a time, and it can build up to the point where it will foul things up.

In a couple different progressives and a turret press, it isn’t uncommon for this combination to produce several thousand rounds without a single non-feeder. If there’s a reloader on your list, consider these stocking-priced (less than $30) problem-solvers.

We took a longer look at both here, just in case—ahem—you aren’t convinced.

Sierra MatchKing Bullets

Not to put too fine a point on it, these are the reloader’s equivalent of socks and underwear: Not long on imagination, gift-selection wise, but essential to comfortable operations.

And by “comfortable operations,” we quite naturally mean hitting what you aim at. We got started with these when they were pretty much the only game in town for sub-MOA accuracy. To say we’ve never looked back isn’t exactly correct—other manufacturers have got some mighty fine long balls too, and we use them with gusto.

New rifles, though, and most of our personal stable still get the Sierra treatment. We can only think of cases where we fouled up—never where a Sierra-topped cartridge did. A while back, their latest version of a favorite, the vaunted 168-grain, .30-caliber MatchKing, appeared on our bench, and we’ve had a chance to wring it out some since.

Suffice it to say that the only reason the acetal resin-tipped MatchKing doesn’t earn a “wow” is because the bar was already so high, and set there by—you guessed it—the regular MatchKing. This should not be confused with there being no difference. When we’re sure we’ve done our part correctly, the TMK performs about 13 to 15 percent better on a consistent basis.

Sierra explains this matter-of-factly: The new tip reduces drag, which results in a higher ballistic coefficient—by about 17 percent by our calculations, and through most of the velocity envelope for our favorite .308/7.62 loads. We haven’t tested this as far out as we’d like, but Sierra says the 168 will now stay supersonic at 1,000 yards. That’s a clear advantage to the F-class guys (can you say “real accuracy nuts?”), but more accuracy is always better, and that means the rest us.

We find them in five calibers and 11 weights on the Sierra website. Now all you’ll need is a sound stocking on a substantial hook to make your shooter smile.

Frank Winn has been studying arms and their relationship to tyranny, meaningful liberty and personal security all his adult life. He has been a firearms safety/shooting instructor for more than 20 years, and earned state, regional and national titles in several competitive disciplines.